Our Certifications

Our Services

What We Do

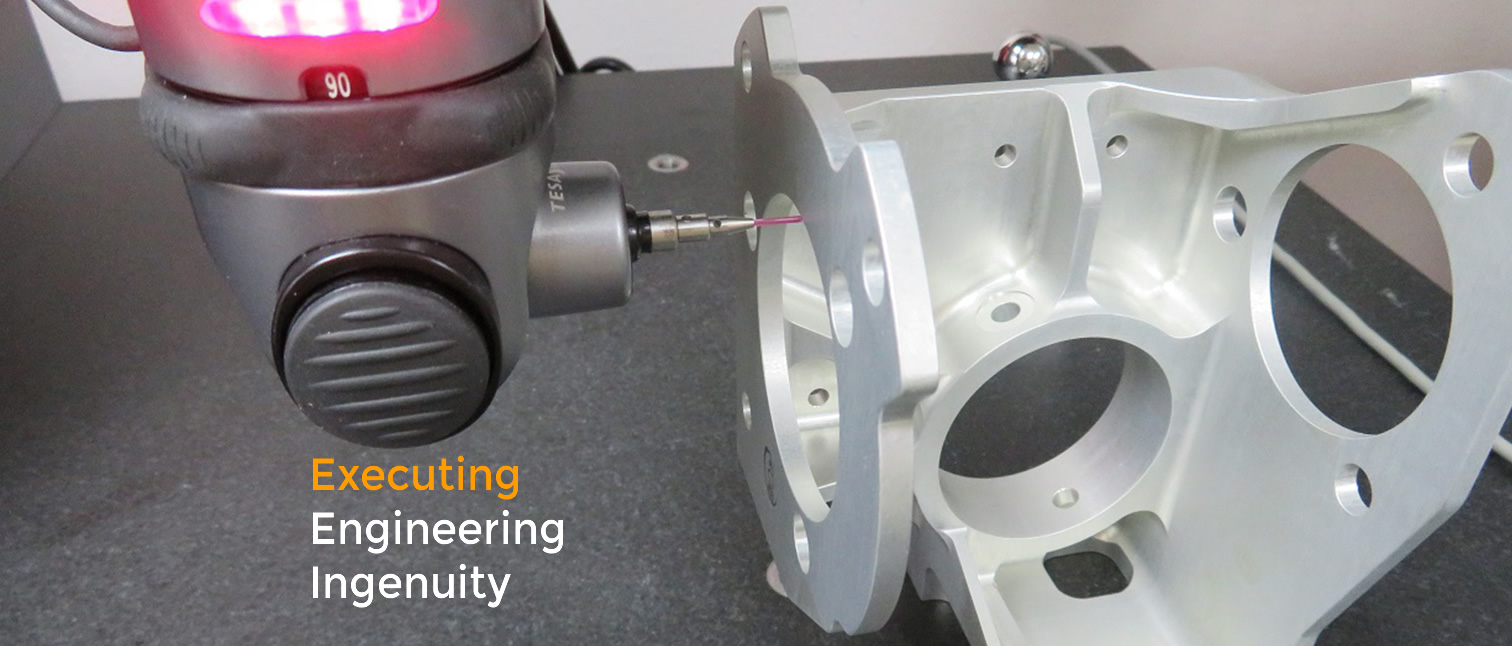

At Dexter Design and Development, we execute engineering ingenuity to deliver absolute precision in CNC machining and end-products that meet exact specifications for form, fit, function and appearance. We are ISO9001:2015/AS9100D certified.

CNC Machining

Advanced state-of-the-art CNC lathe and milling capabilities allow us to stay on the cutting edge of innovation and deliver highly complex parts.

Prototyping

Our team of highly skilled product machinists and tool makers assist with development to ensure maximum efficiencies and performance.

Sub Assembly

We are able to install hardware such as Dowel Pins, Heli-Coils, Keenserts and Pem-Fasteners to meet our clients' sub assembly needs.

Our Company

Who We Are

A minority owned machine shop, Dexter Design and Development is a leader in precision machining and product innovation serving aerospace, high-tech, electronics, and specialty equipment clients. Looking for an experienced CNC machining company? We are a native owned machine shop with a team of highly skilled machining specialists with expertise in producing highly complex parts at maximum efficiencies utilizing a broad range of materials.

Our Latest

What We Make

Precision components on the cutting edge of innovation.